Wang, Z. et al. Inorganic thermal insulation material prepared from pitchstone. J. Build. Eng. 32, 101745 (2020).

Zhang, X., Hu, J., Fan, X. & Yu, X. Naturally grown mycelium-composite as sustainable Building insulation materials. J. Clean. Prod. 342, 130784 (2022).

Xu, Y., Sun, L., Huang, X., Yu, X. & Qian, Y. Superhydrophobic foamed concrete based on response surface method: mix design and its potential application in roofing systems. Structures 69, 107441 (2024).

Mazaherifar, M. H., Coşereanu, C., Timar, C. M. & Georgescu, S. V. Physical and mechanical properties of foam-type panels manufactured from recycled cardboard. Constr. Build. Mater. 411, 134685 (2024).

Annaba, K. et al. Thermomechanical characterization and thermal simulation of a new multilayer mortar and a light-weight pozzolanic concrete for Building energy efficiency. Constr. Build. Mater. 346, 128479 (2022).

Ha, Y. & Jeon, J. Thermogravimetric analysis and pyrolysis characterization of expanded–polystyrene and polyurethane–foam insulation materials. Case Stud. Therm. Eng. 54, 104002 (2024).

Ding, X., Huang, W., Li, Y., Hu, Z. & Shan, Z. Study on retarding feature and retardation mechanism of various retarding materials on gypsum as a construction material: A review. J. Build. Eng. 72, 106569 (2023).

Weimann, K., Adam, C., Buchert, M. & Sutter, J. Environmental evaluation of gypsum plasterboard recycling. Minerals 11, 101 (2021).

Laksham, S. & Hitish, H. Experimental investigations of epoxy-resin-banana-fiber-saw dust bio-composite material for potential application as partitioning board. Mater. Today Proc. https://doi.org/10.1016/j.matpr.2023.01.237 (2023).

River, A. J. & Navarro, J. G. Management of end-of-life gypsum in a circular economy. Woodhead Publ Adv. Constr. Demolition Waste Recycl https://doi.org/10.1016/B978-0-12-819055-5.00005-X (2020).

Li, S. & Chen, G. Agricultural waste-derived superabsorbent hydrogels: preparation, performance, and socioeconomic impacts. J. Clean. Prod. 251, 119669 (2020).

Ullah, K. et al. Assessing the lignocellulosic biomass resources potential in developing countries: A critical review. Renew. Sustain. Energy Rev. 51, 682–698 (2015).

Debnath, B., Haldar, D. & Purkait, M. K. A critical review on the techniques used for the synthesis and applications of crystalline cellulose derived from agricultural wastes and forest residues. Carbohydr. Polym. 273, 118537 (2021).

Sahoo, K., Kumar, A. & Chakraborty, J. P. A comparative study on valuable products: bio-oil, biochar, non-condensable gases from pyrolysis of agricultural residues. J. Mater. Cycles Waste Manag. 23, 186–204 (2021).

Deshpande, M. V., Kumar, N., Pillai, D., Krishna, V. V. & Jain, M. Greenhouse gas emissions from agricultural residue burning have increased by 75% since 2011 across India. Sci. Total Environ. 904, 166944 (2023).

Ravindra, K., Singh, T. & Mor, S. Emissions of air pollutants from primary crop residue burning in India and their mitigation strategies for cleaner emissions. J. Clean. Prod. 208, 261–273 (2019).

IPCC. Intergovernmental Panel on Climate Change (IPCC). (2006). https://www.ipcc-nggip.iges.or.jp/public/gl/invs1.html

Kanabkaew, T. & Kim Oanh, N. T. Development of Spatial and Temporal emission inventory for crop residue field burning. Environ. Model. Assess. 16, 453–464 (2011).

ESED. Agricultural Statistics at a Glance. (2023). https://desagri.gov.in/document-report-category/agriculture-statistics-at-a-glance/

Sahai, S., Sharma, C., Singh, S. K. & Gupta, P. K. Assessment of trace gases, carbon and nitrogen emissions from field burning of agricultural residues in India. Nutr. Cycl. Agroecosystems. 89, 143–157 (2011).

Singh, J. & Gu, S. Biomass conversion to energy in India—A critique. Renew. Sustain. Energy Rev. 14, 1367–1378 (2010).

Vallack, H., Rypdal, K., Branco, G., Hao, J. & Bhattacharya, S. The Global Atmospheric Pollution Forum Air Pollutant Emission Inventory Manual. (2010).

Firoozi, A. A., Firoozi, A. A., Oyejobi, D. O., Avudaiappan, S. & Flores, E. S. Emerging trends in sustainable Building materials: technological innovations, enhanced performance, and future directions. Results Eng. 24, 103521 (2024).

Elfaleh, I. et al. A comprehensive review of natural fibers and their composites: an eco-friendly alternative to conventional materials. Results Eng. 19, 101271 (2023).

Chen, L. et al. Conversion of waste into sustainable construction materials: A review of recent developments and prospects. Mater. Today Sustain. 27, 100930 (2024).

Aramwit, P., Sheng, D. C. V., Krishna Moorthy, D., Guna, G., Reddy, N. & V. & Rice husk and Coir fibers as sustainable and green reinforcements for high performance gypsum composites. Constr. Build. Mater. 393, 132065 (2023).

Hassan, T. et al. Acoustic, mechanical and thermal properties of green composites reinforced with natural fibers waste. Polymers 12, 654 (2020).

Rojas, C. et al. Thermal insulation materials based on agricultural residual wheat straw and corn husk biomass, for application in sustainable buildings. Sustain. Mater. Technol. 20, e00102 (2019).

Sheng, D. D. C. V., Ramegowda, N. S., Guna, V. & Reddy, N. Groundnut shell and Coir reinforced hybrid bio composites as alternative to gypsum ceiling tiles. J. Build. Eng. 57, 104892 (2022).

Maderuelo-Sanz, R. et al. Mechanical, thermal and acoustical evaluation of biocomposites made of agricultural waste for ceiling tiles. Appl. Acoust. 191, 108689 (2022).

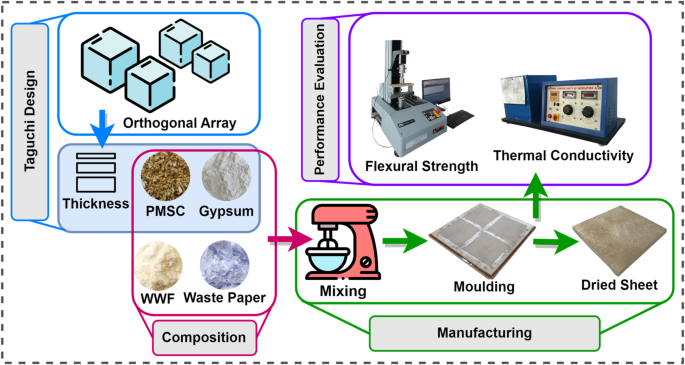

Ejaz, M. F. et al. Physico-Mechanical characterization of Gypsum-Agricultural waste composites for developing Eco-Friendly false ceiling tiles. Sustainability 14, 9797 (2022).

Guna, V. et al. Wool and Coir fiber reinforced gypsum ceiling tiles with enhanced stability and acoustic and thermal resistance. J. Build. Eng. 41, 102433 (2021).

Guna, V. et al. Groundnut shell / rice husk agro-waste reinforced polypropylene hybrid biocomposites. J. Build. Eng. 27, 100991 (2020).

Guna, V., Ilangovan, M., Hu, C., Venkatesh, K. & Reddy, N. Valorization of sugarcane Bagasse by developing completely biodegradable composites for industrial applications. Ind. Crops Prod. 131, 25–31 (2019).

Hossain, S. K. S. & Roy, P. K. Fabrication of sustainable ceramic board using solid-wastes for construction purpose. Constr. Build. Mater. 222, 26–40 (2019).

Bal, H., Jannot, Y., Gaye, S. & Demeurie, F. Measurement and modelisation of the thermal conductivity of a wet composite porous medium: laterite based bricks with millet waste additive. Constr. Build. Mater. 41, 586–593 (2013).

Bal, H., Jannot, Y., Quenette, N., Chenu, A. & Gaye, S. Water content dependence of the porosity, density and thermal capacity of laterite based bricks with millet waste additive. Constr. Build. Mater. 31, 144–150 (2012).

Karbuz, P., Dogu, M. & Ozbek, B. Manufacturing of hexagonal cross-section thermoplastic matrix composite parts with automatic filament winding system. J. Manuf. Process. 129, 62–76 (2024).

Prakash, D. Development of PCM tile for residential buildings in hot and dry climate: design and optimization. J. Eng. Appl. Sci. 71, 202 (2024).

Esangbedo, M. O. & Samuel, B. O. Application of machine learning and grey Taguchi technique for the development and optimization of a natural fiber hybrid reinforced polymer composite for aircraft body manufacture. Oxf. Open. Mater. Sci. 4, itae004 (2024).

Sanman, S., Manjunath, A., P Prashanth, K., Shadakshari, R. & K Sunil, S. An experimental study on two body abrasive wear behavior of natural fiber reinforced hybrid polymer matrix composites using Taguchi analysis. Mater. Today Proc. 72, 2021–2026 (2023).

Binoj, J. S. et al. Taguchi’s optimization of Areca fruit husk Fiber mechanical properties for polymer composite applications. Fibers Polym. 23, 3207–3213 (2022).

Toapanta, O. G., Paredes, J., Meneses, M. & Salinas, G. Validation of DOE factorial/taguchi/surface response models of mechanical properties of synthetic and natural Fiber reinforced epoxy matrix hybrid material. Polymers 16, 2051 (2024).

Onyekwere, O. S., Oladeinde, M. H. & Edokpia, R. O. Multi-Response optimization of bamboo Fiber reinforced unsaturated polyester composites using hybrid Taguchi – Grey relational analysis method. J. Ind. Prod. Eng. 38, 98–107 (2021).

Sampath, B. et al. Experimental comparative study of banana fiber composite with glass fiber composite material using Taguchi method. Mater. Today Proc. 49, 1475–1480 (2022).

Antony, J. et al. Application of Taguchi design of experiments in the food industry: a systematic literature review. Total Qual. Manag Bus. Excell. 35, 687–712 (2024).

Haniel, Bawono, B. & Anggoro, P. W. Optimization of characteristics polymer composite reinforced Kenaf and jute Fiber using Taguchi-Response surface methodology approach. J. Nat. Fibers. 20, 2204453 (2023).

Jaisingh Sheoran, A. & Kumar, H. Fused deposition modeling process parameters optimization and effect on mechanical properties and part quality: review and reflection on present research. Int. Conf. Mech. Energy Technol. 21, 1659–1672 (2020).

Gupta, D., Das, A. & Mitra, S. Role of modeling and artificial intelligence in process parameter optimization of biochar: A review. Bioresour Technol. 390, 129792 (2023).

Bayrak, Z. U. & Celik, N. Determining the effects of operating conditions on current density of a PEMFC by using Taguchi method and ANOVA. Arab. J. Sci. Eng. 49, 10741–10752 (2024).

Jiang, L. et al. Optimization of multi-stage constant current charging pattern based on Taguchi method for Li-Ion battery. Appl. Energy. 259, 114148 (2020).

Soni, A., Patel, R. M., Kumar, K. & Pareek, K. Optimization for maximum extraction of solder from waste PCBs through grey relational analysis and Taguchi technique. Min. Eng. 175, 107294 (2022).

Behera, A., Sahu, P. S. & Patel, S. K. Application of Taguchi methodology for optimization of process parameters in laser bending of Al sheet. 10th Int. Conf. Mater. Process. Charact. 26, 2323–2327 (2020).

Sutherland, L. S., Shenoi, R. A. & Lewis, S. M. Size and scale effects in composites: II. Unidirectional laminates. Compos. Sci. Technol. 59, 221–233 (1999).

Atencio, E., Plaza-Muñoz, F., Muñoz-La Rivera, F. & Lozano-Galant, J. A. Calibration of UAV flight parameters for pavement pothole detection using orthogonal arrays. Autom. Constr. 143, 104545 (2022).

Chen, G. L., Chen, G. B., Li, Y. H. & Wu, W. T. A study of thermal pyrolysis for castor meal using the Taguchi method. Energy 71, 62–70 (2014).

Day, L., Augustin, M. A., Batey, I. L. & Wrigley, C. W. Wheat-gluten uses and industry needs. Trends Food Sci. Technol. 17, 82–90 (2006).

Drago, S. R. & González, R. J. Foaming properties of enzymatically hydrolysed wheat gluten. Nutr. Meet Food. 1, 269–273 (2000).

Markowski, M., Żuk-Gołaszewska, K. & Kwiatkowski, D. Influence of variety on selected physical and mechanical properties of wheat. Ind. Crops Prod. 47, 113–117 (2013).

Wieser, H., Koehler, P. & Scherf, K. A. Chapter 5 – Wheat-based Raw materials. in Wheat – An Exceptional Crop (eds Wieser, H., Koehler, P. & Scherf, K. A.) 103–131 (Woodhead Publishing, doi:https://doi.org/10.1016/B978-0-12-821715-3.00005-8. (2020).

ASTM C177. Test method for Steady-State heat flux measurements and thermal transmission properties by means of the Guarded-Hot-Plate apparatus. (19) https://doi.org/10.1520/C0177-19

Mondal, M. S., Hussain, S. Z., Roy, P. & Halder, C. Development of high-performance composite via innovative route using water hyacinth extracted nanocellulose and analysis of its physical properties. Heliyon 9, e23095 (2023).

Raju, B. S., Manjunatha, L. H., Jagadeeswaran, N. & Santosh & Fabrication & characterization of ZnS micro particulate filled glass and jute fibre reinforced hybrid polymer composites. Int. Conf. Recent. Res. Emerg. Trends Mater. Mech. Eng. 20, 125–133 (2020).

ASTM C473. Standard Test Methods for Physical Testing of Gypsum Panel Products, C11 Committee. http://www.astm.org/cgi-bin/resolver.cgi?C473-15 (2015). https://doi.org/10.1520/C0473-15

Aghaee, K., Yazdi, M. A. & Yang, J. Flexural properties of composite gypsum partition panel. Proc. Inst. Civ. Eng. Eng. Sustain. 168, 258–263 (2015).

Rubio-Avalos, J. C. et al. Flexural behavior and microstructure analysis of a gypsum-SBR composite material. Mater. Lett. 59, 230–233 (2005).

Selamat, M. E. et al. Comparative study of oil palm trunk and rice husk as fillers in gypsum composite for Building material. Constr. Build. Mater. 197, 526–532 (2019).

Karaca, E., Çakar, T. & Karaca, M. Hüseyin Miraç gül, H. Designing restorative landscapes for students: A Kansei engineering approach enhanced by VR and EEG technologies. Ain Shams Eng. J. 15, 102901 (2024).

Nghiep, T. N., Sarhan, A. A. D. & Aoyama, H. Analysis of tool Deflection errors in precision CNC end milling of aerospace aluminum 6061-T6 alloy. Measurement 125, 476–495 (2018).

Hsiang, S. H. & Lin, Y. W. Investigation of the influence of process parameters on hot extrusion of magnesium alloy tubes. Seventh Asia Pac. Conf. Mater. Process. 7th APCMP 2006, 192–193 (2007).

Vidakis, N. et al. Critical quality indicators of high-performance polyetherimide (ULTEM) over the MEX 3D printing key generic control parameters: prospects for personalized equipment in the defense industry. Def. Technol. https://doi.org/10.1016/j.dt.2024.08.001 (2024).

Bao, M., Lin, J., Zhang, F. & Yang, J. Discrete element method study of parameter optimization and particle mixing behaviour in a soil mixer. Particuology 81, 1–14 (2023).

Grujicic, M. & Chittajallu, K. M. Design and optimization of polymer electrolyte membrane (PEM) fuel cells. Appl. Surf. Sci. 227, 56–72 (2004).

Hai, T. et al. Energy and environmental analyses of a sustainable multi-generation municipal solid waste-to-energy integrated system for hydrogen production. Process. Saf. Environ. Prot. 177, 307–321 (2023).

Chaudhary, N. Parametric sensitivity analysis to investigate the effects of operating and design parameters on single direct methane steam reforming solid oxide fuel cell performance and thermal impacts generation. Energy Convers. Manag X. 18, 100374 (2023).

Rana, R., Gill, A. S., Deol, P. K. & Kaur, I. P. Investigation of cellulose acetate electrospun films for controlled drug permeability. J. Drug Deliv Sci. Technol. 91, 105263 (2024).

Aslan, N. & Ünal, İ. Multi-response optimization of oil agglomeration with multiple performance characteristics. Fuel Process. Technol. 92, 1157–1163 (2011).

Dubey, A. K. & Yadava, V. Optimization of Kerf quality during pulsed laser cutting of aluminium alloy sheet. J. Mater. Process. Technol. 204, 412–418 (2008).

Ateş, F. & Erginel, N. The regression analysis of fast pyrolysis product yields and determination of product quality. Spec. Sect. ACS Clean. Coal. 102, 681–690 (2012).

Bhatti, U. A. et al. Global production patterns: Understanding the relationship between greenhouse gas emissions, agriculture greening and climate variability. Environ. Res. 245, 118049 (2024).

Gulcan, B., Eksioglu, S. D., Song, Y., Roni, M. & Chen, Q. Optimization models for integrated biorefinery operations. Optim. Lett. 16, 909–951 (2022).

Rueda, R., Cuéllar, M. P., Ruiz, L. G. B. & Pegalajar, M. C. A similarity measure for straight line programs and its application to control diversity in genetic programming. Expert Syst. Appl. 194, 116415 (2022).

Ghosh, S., Chandra Mandal, M. & Ray, A. Exploring the influence of critical parameters on green supply chain management performance of small and medium-sized enterprise: an integrated multivariate analysis-robust design approach. Clean. Logist Supply Chain. 4, 100057 (2022).

Lu, Y. et al. Influence mechanism of Magnetron sputtering process parameters on diamond surface preprocessing interface for chip heat sink. Diam. Relat. Mater. 150, 111695 (2024).

Balachandran, M., Devanathan, S., Muraleekrishnan, R. & Bhagawan, S. S. Optimizing properties of nanoclay–nitrile rubber (NBR) composites using face centred central composite design. New. Rubber Mater. Test. Methods Process. 35, 854–862 (2012).

Hassannayebi, E., Boroun, M., Alaei Jordehi, S. & Kor, H. Train schedule optimization in a high-speed railway system using a hybrid simulation and meta-model approach. Comput. Ind. Eng. 138, 106110 (2019).

Kiaee, N. & Aghaie-Khafri, M. Optimization of gas tungsten Arc welding process by response surface methodology. Mater. Des. 1980–2015. 54, 25–31 (2014).

Jian, S. et al. Optimizing hydration and performance of phosphogypsum based cementitious system through multiphase composites. Constr. Build. Mater. 472, 140848 (2025).